Home > Painting > Powder coating

POWDER COATING PROCESS

DEFINITION OF THE PROCESS

The powder coating of galvanized steel, also known as “duplex treatment”, is a specialty of the GALVA UNION group.

Powder coating consists of applying a powder coating to a pre-prepared metal part and then baking it in an oven.

DECO GALVA meets the requirements of the QUALISTEELCOAT specifications and the triple certification ISO 9001 – 14001 – 18001 in order to maximize the reliability, safety and performance of its powder coating processes.

Certification QUALISTEELCOAT

Certification 9001

STEPS IN THE PROCESS:

1. The chemical pickling

This first step eliminates pollutants and zinc salts. It is a homogeneous, non-aggressive and controllable process that contributes to the protection of the substrate.

2. Rinsing the cleaned piece:

Then, we proceed with rinsing with city water and demineralized water (4 cascading rinses) to eliminate the mineral salts causing delamination.

3. Degassing:

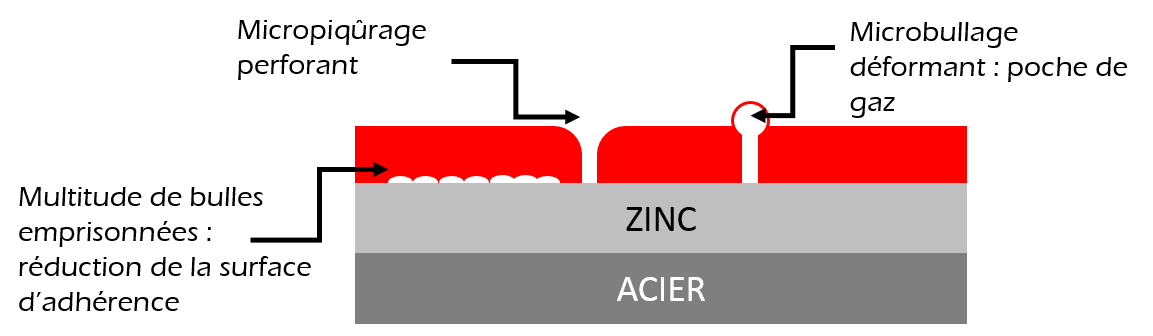

This step avoids the presence of hydrogen or gas causing defects in adhesion and appearance. This part of the process limits the occurrence of micro-bubbling or micropitting (see figure opposite).

4. Film-forming conversion:

This mandatory phase before the application of the paint layer to obtain good adhesion and good resistance to salt spray test.

5. Application of the powder:

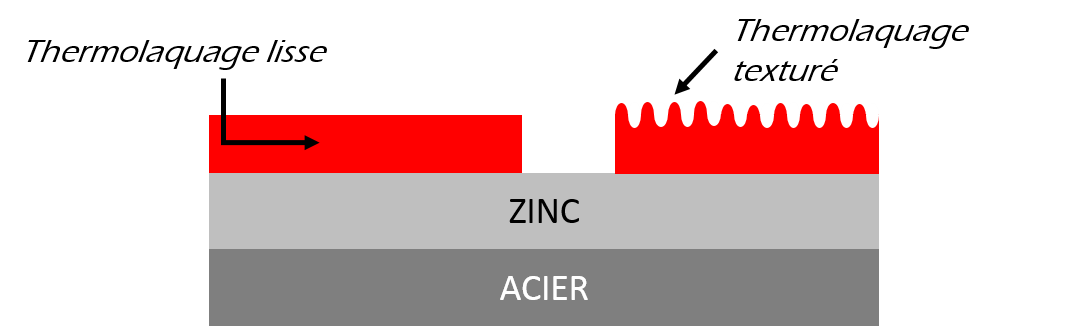

We apply either manually or automatically one or more layers of high performance powder and architectural quality.

This coating is deposited by electrostatic effect and then polymerized in an oven between 160 and 200 ° C.

The next steps of the process differ according to the ranges used:

- For DECOCEAN, the application of a second layer of powder will be necessary to protect the coating of corrosivity categories of environments (C4 / C5).

- In the case of a DECOSTEEL process, a sublimation transfer of inks will be applied to the piece

THE ADVANTAGES OF THE POWDER COATING PROCESS :

- The most aesthetic of paint coatings

- Clean coating: neither TGIC nor solvent

- A long life

The quality of the powder coating also depends on the technical characteristics of the powder.

The use of an architectural quality polyester powder paint makes it possible to offer the best characteristics of resistance to external atmospheres.

CHOOSE A PLANT