Passivation

WHY USE THE PASSIVATION PROCESS

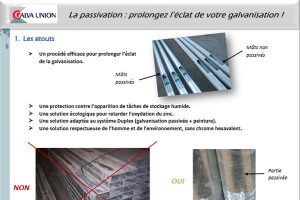

An effective method for prolonging the brightness of the galvanization.

At the end of the zinc bath, the freshly galvanized parts have a shiny appearance. After a few days of exposure to the atmosphere, the zinc reacts with the surrounding elements and a gray or whitish patina is formed. The insoluble, adherent and protective formed layer has zinc as the main constituent basic zinc carbonate. It is reflected in appearance by a gradual decrease in the brightness of the galvanization. This is a normal phenomenon, natural and desirable, because it is what makes it possible to protect the steel durably against corrosion.

Passivation is an effective process that slows the formation of this patina and prolongs the brightness of the galvanization

Protection against the appearance of wet storage stains

In some cases, the constitution of this patina may be thwarted and whitish wet storage stains may form on the surface of the piece. These whitish stains, more commonly known as “white rust,” occur when water from rain or condensation has been trapped between stacked parts during storage or transportation. They consist in particular of hydroxide and zinc oxide, powdery products generally not adherent and non-protective. This phenomenon has the disadvantage of poor presentation by its appearance, but in no way alter the quality of the galvanization.

Passivation is an effective method to avoid the formation of these whitish spots in case of high humidity.

An ecological solution to delay the oxidation of zinc

In addition to prolonging the brightness of zinc and delaying its oxidation, passivation also has the advantage of being an environmentally friendly solution and not dangerous to the health of individuals. The passivation solutions selected by ZINQ companies do not contain hexavalent chromium. This is part of the progress policy approach that the companies of the ZINQ group are leading to become recognized actors of sustainable economic development.

Description of the process

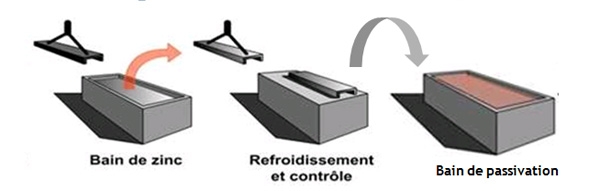

This process involves immersing the freshly galvanized parts at a certain temperature in the passivation bath, located just after the zinc bath in the galvanizing process, to cover the piece with a protective film.

- The part is galvanized by immersion in the molten zinc.

- The cooling stage makes it possible to control the temperature of the parts before passivation.

- Passivation involves immersing the galvanized steel in an aqueous solution bath containing the protective components of zinc

This service is offered by several galvanizing companies of the ZINQ group.

Multimedia

CHOOSE A PLANT